What is machining

Release time:

2025-01-04

【Summary】Qing County machining, or mechanical processing, refers to the process of changing the shape, size, or performance of a workpiece through mechanical equipment. Below is a detailed introduction to machining:

Qing County Machining, that is, machining, refers to the process of changing the shape, size, or performance of a workpiece through mechanical equipment. Below is a detailed introduction to machining:

I. Classification

Machining can be divided into cutting processing and pressure processing based on the differences in processing methods. Cutting processing is the process of removing excess material from the workpiece through the relative motion between the tool and the workpiece, thereby obtaining the desired shape, size, and surface quality. Pressure processing, on the other hand, uses mechanical force to cause plastic deformation of metals at room temperature or in a heated state, thus obtaining workpieces of the desired shape and size. In addition, machining can also be divided into manual processing and CNC processing based on the mode of operation:

- Manual Processing: refers to the method of processing various materials through the manual operation of mechanical workers on milling machines, lathes, drilling machines, and saws.

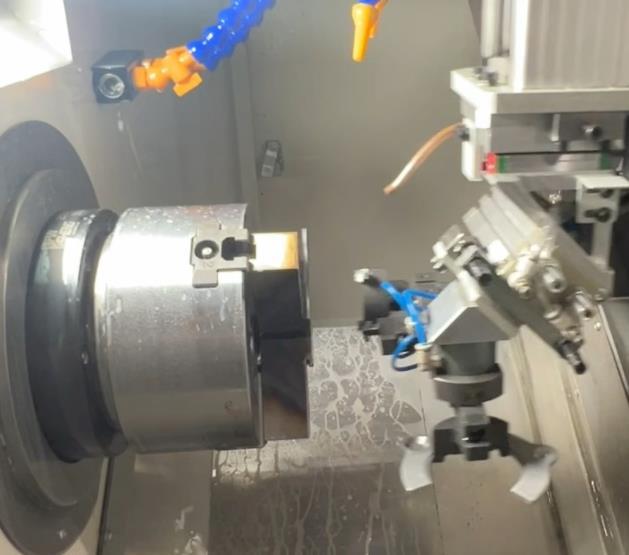

- CNC Processing: uses CNC technology to control the movement of machine tools, achieving automated processing. CNC processing features high precision, high efficiency, and high flexibility, and is widely used in the processing of various complex-shaped parts.

II. Process Flow

The process flow of machining usually includes the following steps:

- Production Preparation: includes the transportation and storage of raw materials, as well as the preparation work for production, such as the manufacturing of blanks.

- Part Processing: through processes such as cutting, grinding, boring, and tapping, the blank is processed into parts that meet design requirements.

- Heat Treatment: heat treatment of processed parts to improve their mechanical properties and corrosion resistance.

- Assembly and Debugging: assembling the processed parts and debugging to ensure the performance and safety of the equipment.

III. Applications

Machining occupies an important position in the manufacturing industry and is widely used in the following fields:

- Part Manufacturing: such as the manufacturing of parts for machinery and equipment like automobiles and airplanes.

- Equipment Maintenance: repairing or replacing damaged or worn equipment parts.

- Craft Production: using machining technology to produce various crafts.

- Customized Product Processing: precise processing according to customer needs to meet consumer demand for personalized products.

IV. Development Trends

With the continuous advancement of technology and the development of the global economy, the machining industry shows the following development trends:

- Intelligentization: achieving automation, intelligence, and flexibility in the production process by integrating technologies such as artificial intelligence, the Internet of Things, and big data with production lines.

- Industry 4.0: achieving data collection, analysis, and control in the production process through technologies such as the Internet of Things, big data, and cloud computing, improving production efficiency, reducing costs, and enhancing product quality.

- Green Manufacturing: reducing energy consumption, lowering waste emissions, and improving resource utilization in the production process to achieve sustainable development.

- High-Precision Processing: as product quality requirements continue to rise, machining will gradually develop towards high-precision processing.

- Flexible Production: achieving rapid adjustment and transformation of production line equipment to adapt to changes in market demand.

V. Industry Terms and Conditions

The machining industry has many professional terms; below are some common terms and their explanations:

- Turning: a processing method that uses a lathe to perform rotary cutting on a workpiece.

- Milling: a processing method that uses a milling machine to perform flat or curved surface cutting on a workpiece.

- Drilling: a processing method for drilling round holes in a workpiece.

- Grinding: a processing method that uses abrasives to perform micro-cutting on the surface of a workpiece.

- Boring: a method for enlarging or finishing existing holes.

- Tapping: a processing method for creating threads inside a hole.

- Wire Cutting: a processing method that uses fine wire for precise cutting of a workpiece.

- Electrical Discharge Machining: a method of processing a workpiece using the heat generated by electrical discharge.

In summary, machining is an important manufacturing process with a wide range of applications and development prospects. With the continuous advancement and innovation of technology, the machining industry will continue to see the emergence of new materials, new processes, and new technologies, driving the continuous development and progress of the industry.

TAG:

RELATED INFORMATION

2025-01-20

How much do you know about stainless steel sheet metal processing?

2025-01-18

What are the inspection standards for sheet metal processing chassis and cabinets?

2025-01-17

What are the main processes of sheet metal processing?

2025-01-16

What is the process flow of the chassis cabinet?

FAX

ADD

Gengguantun Industrial Development Zone, Qingxian County, Hebei Province, China

WeChat applet