2025-01-20

How much do you know about stainless steel sheet metal processing?

2025-01-18

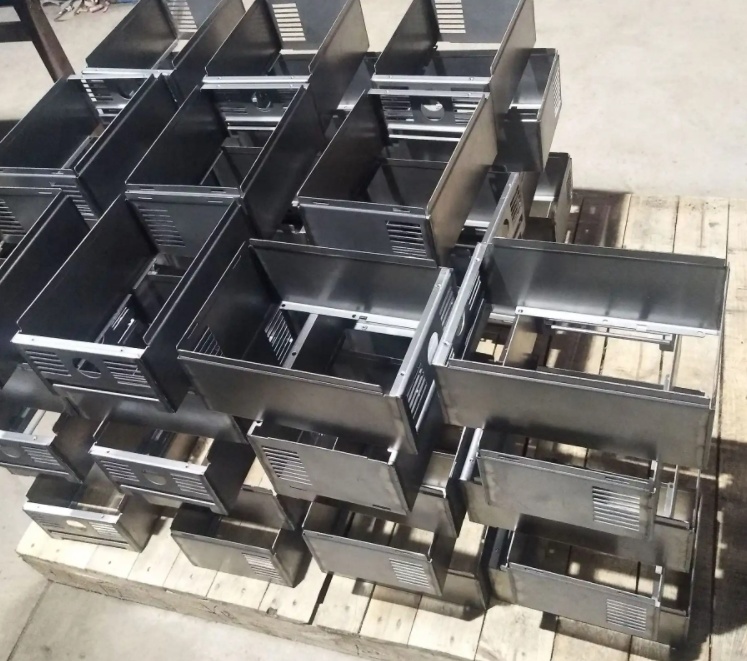

What are the inspection standards for sheet metal processing chassis and cabinets?

2025-01-17

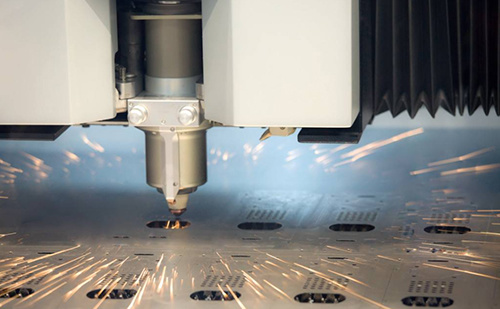

What are the main processes of sheet metal processing?

2025-01-16

What is the process flow of the chassis cabinet?

2025-01-15

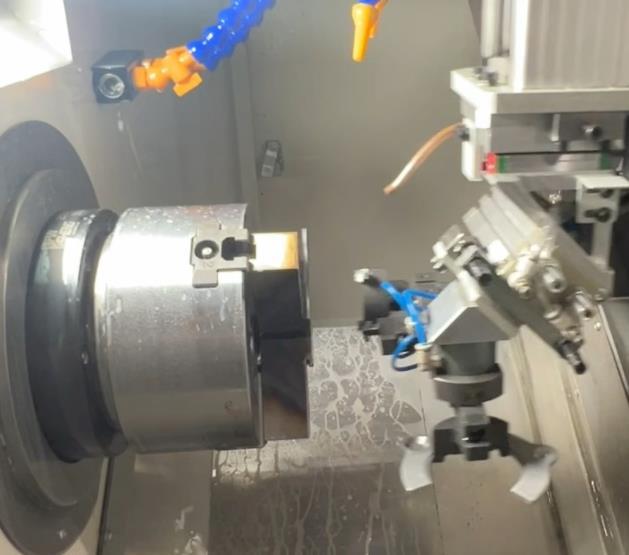

Machining Inspection Specifications and Standards

2025-01-14

What is sheet metal processing?

2025-01-13

Sheet metal shell processing manufacturer

2025-01-11

Which sheet metal processing manufacturer in Qingxian is good?

2025-01-10

What is the difference between machining and sheet metal processing?

2025-01-09

What are the advantages of precision sheet metal processing?

2025-01-09

What is precision sheet metal processing

2025-01-08

What equipment is used for sheet metal processing of chassis and cabinets?

2025-01-08

2025-01-07

What are the advantages of sheet metal processing?

2025-01-07

What are the processes involved in the sheet metal processing of chassis and cabinets?

2025-01-06

What is a sheet metal processing chassis cabinet?

2025-01-04

What are the advantages of machining?

2025-01-04

2025-01-03

What equipment is used for sheet metal processing of chassis and cabinets?

2025-01-03

What is sheet metal processing?

FAX

ADD

Gengguantun Industrial Development Zone, Qingxian County, Hebei Province, China

WeChat applet